Tired of dusty jobsites or the hazards associated with open-air abrasive blasting? Try a vapor blaster from our AmphiBlast Family or one of the GBT units! These units are portable, easy to use, and help reduce the need for containment and other common jobsite needs. Look no further than our top-quality vapor blasting machines for rent. With precision at the forefront, our machines are designed to deliver unrivaled performance and results.

Unleash the power of precision with our cutting-edge vapor blasting technology. Whether you’re working on automotive, aerospace, marine, or industrial projects, our machines are up to the task. Built with superior craftsmanship and advanced features, they offer unparalleled control, efficiency, and versatility.

Experience the difference of our vapor blasting machines as they effortlessly remove rust, paint, corrosion, and other contaminants from a variety of surfaces. Achieve a pristine finish with minimal effort and maximum efficiency.

With our commitment to customer satisfaction, we provide not only high-quality machines but also exceptional customer service and support. Our team of experts is ready to assist you in choosing the perfect machine to suit your specific needs and offer ongoing support after purchase.

Don’t settle for anything less than perfection. Discover the power of precision and elevate your blasting game with our top-quality vapor blasting machines.

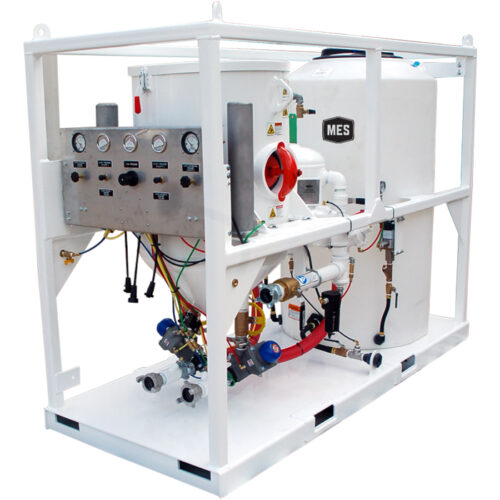

At MES, we only recommend two brands of vapor blasting units: The AmphiBlast Family and The Greener Blast units. The performance of these units are second to none in the industry, and both have their strengths depending upon the need of the customer.

4.5 CF to 160 CF Options Available.

Reach out to MES today to discuss your upcoming needs so we can make the best recommendation for your job!